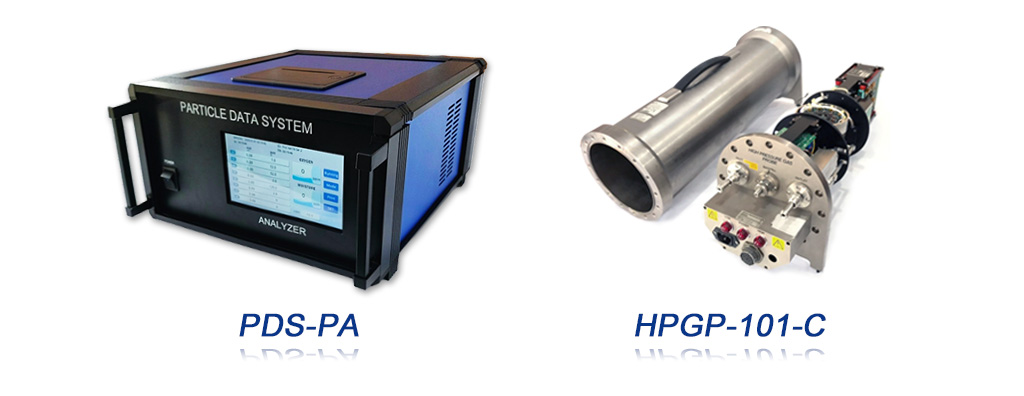

Particle Data System

HPGP-101-C,High-Pressure Gas, Leading Particle Water Oxygen Analysis Integration Technology

Particle Analyzer with Touch Screen Interface Design and Real-time Monitoring Capability

HPGP-101-C, HPGP-101-C,High-Pressure Gas,Particle Analyzer, equipped with advanced technology and precision sensors, is a precision testing instrument used in the semiconductor industry. The presence of particles significantly affects product quality and performance during semiconductor manufacturing processes. The high-pressure particle analysis system accurately detects and analyzes tiny particles in semiconductor processes. With high sensitivity and precision, particle analysis can detect particles at the nanoscale or even smaller. It enables tracking and monitoring of particle generation, distribution, and evolution in semiconductor processes, providing crucial information and data support.

The Particle Data System is a state-of-the-art particle analysis device that incorporates modern features, including an advanced touch screen interface. These features not only enhance the user experience but also effectively improve the overall performance of the analysis instrument. The system injects new vitality into the semiconductor industry’s production workflow, saving valuable time and resources.

Particle Analyzer Precision Particle Analysis Detection and Real-time Alerts

Particle Analyzer,The Particle Data System possesses highly accurate particle analysis detection capability, allowing for real-time monitoring and alerting of abnormal particle counts in machinery and equipment. This critical feature not only provides real-time data alerts for users to respond promptly but also prevents potential issues, ensuring stable and reliable operation of the machinery and equipment. The particle analysis instrument offers precise and efficient analytical solutions for machinery and equipment. Whether in the manufacturing industry, automation field, or other domains, the system delivers high-efficiency analytical solutions to customers, enhancing overall productivity value and competitive advantage.

| Specifications | |

|---|---|

| Number of sensors | 1 |

| Sampling interval | 1 second to 99:59:59 (hh:mm:ss); programmable or manual |

| Sampling mode | Single, continuous, or manual |

| Delay time | 5 seconds to 99:59:59 (hh:mm:ss); programmable |

| Data management and analysis | Facility Net |

| Computer interface | RS-232 / RS-485, bi-directional |

| Power | 100-240VAC ,50/60 Hz 0.8A |

| Environment | Temperature: 32°F- 104°F ( 0°C – 40°C). Humidity: noncondensing. Altitude: 0 to 20,000 ft. (6,098 m) |

| Dimensions (L,W,H) | 42cm*35cm*19cm |

| Weight | 5kg |

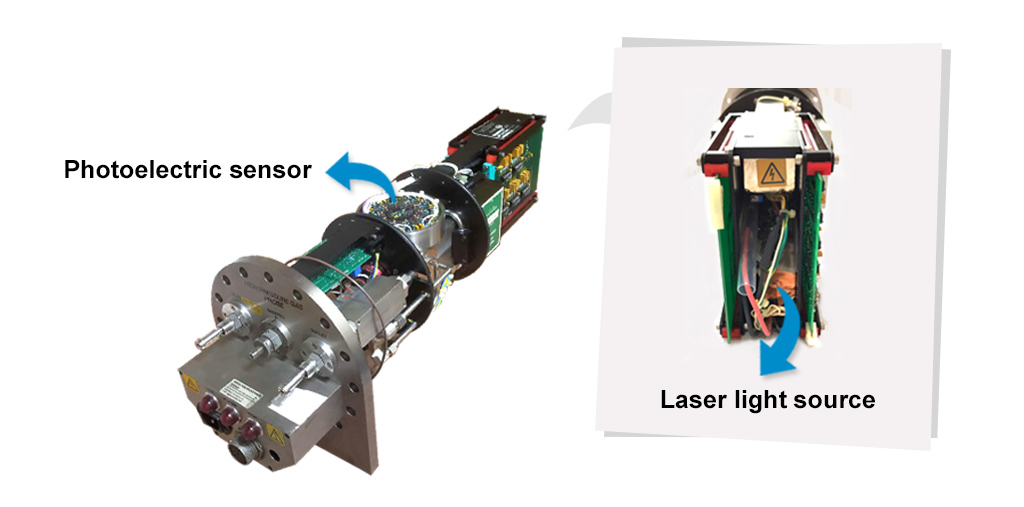

High-Pressure Gas Detector HPGP-101-C: Upgraded Research Project for Enhanced Detection Capability

Upgrade of Laser Light Source and Photosensitive Components in Particle Analysis Instrument, Achieving Particle Detection Size of 0.02um

The HPGP-101-C (High-Pressure Gas Probe) has officially launched the “HPGP-101-C High-Pressure Gas Probe Circuit Upgrade Research Project,” aiming to improve the product’s detection capability. This upgrade project incorporates crucial technological advancements, including advanced laser light sources and photosensitive components, enabling the equipment to accurately detect tiny particles as small as 0.02um. It finds wide applications in particle detection and monitoring within high-pressure gas environments. This upgrade project brings significant breakthroughs to the product, further enhancing its detection capability and accuracy. With the new laser light source and photosensitive components, the HPGP-101-C High-Pressure Gas Probe can efficiently detect and identify particles as small as 0.02um, providing more detailed and precise detection results.

This upgrade project involves retrofitting existing equipment to enhance its identification capability. Through the upgraded HPGP-101-C High-Pressure Gas Probe, users can comprehensively analyze the distribution and quantity of fine particles in high-pressure gas environments, enabling them to take appropriate measures for ensuring air quality particle analysis monitoring. Whether in industrial sectors, research institutions, or other related fields, the launch of the HPGP-101-C High-Pressure Gas Probe upgrade project will further drive the development and expanded application of detection technology. The upgrade solution not only offers higher detection capability but also provides customers with more accurate, convenient, and reliable detection solutions.

Features:

| Type: | Testing and gas sampling. |

|---|---|

| Measured substance: | Gas |

| Application: | Suitable for high-pressure applications. |

| Fields: | Process, safety, monitoring. |

| Other features: | Stainless steel construction, inline design. |

Description:

High-tech manufacturing processes often require high-purity gases. The HPGP-101-C High-Pressure Gas Probe System provides reliable online pollution monitoring for process gases under pipeline pressure. This high-pressure gas probe system is compatible with oxygen, hydrogen, and most non-toxic gases, making it suitable for monitoring various reactive gas applications. It accelerates the qualification process of process gas distribution systems and detects particle contaminants in the gas before they can impact performance. The high-pressure gas probe system is connected to the Particle Data System (PDS-E) via Ethernet, allowing it to collect and report data captured by the probe.

| Particle Size Range: | 0.02 – 5.0 µm |

|---|---|

| High-Pressure Gas Probe System | HPGP-101-C |

Features

- Safety containment vessel

- Oxygen and hydrogen compatibility

- 0.02μm sensitivity at 0.1SCFM

- Eight particle channels

- Line pressures from 40 to 150psig

- Passive laser cavity

- Parallel processing array detector system

Benefits

- Verifies gas quality

- Detects process upsets

- Quantifies impact of system changes

- Provides accurate particle sizing

- Uses Facility Net Software for comprehensive data storage, management, reports and alarms

- Passive cavity design requires infrequent maintenance

- Inert gas purge ensures safety

- Leakage of sample gas to vessel discontinues power to electronics