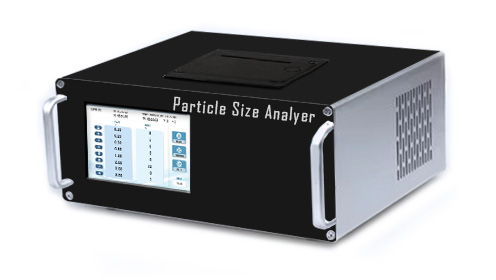

儀表儀器定製

設備解析未知通訊

面臨停產的工業設備,一般在機器送修時,設備間的訊號連結往往是相當凌亂的。工程師需要透過深入的解析,以精密方式處理拆解檢測訊息的方式,辨識並整理設備間的通訊訊號,進而彙整訊號的來源。這項技術不僅能找出設備本身的通訊協定方式,因而讓儀器設備可額外連接更多的附加設備,通過正確的通訊方式進行分析、儀器數據監測、量測..等功能,以達到整合多項功能為一機的目的。

儀表儀器設備,可以客製化的部分有哪些?

從無到有的功能構想設計、電控規劃、機構整合、電路配置到儀器打樣、製作生產,如果您找不到適合的廠商幫您做訂製儀器,小量客製化的服務是我們服務項目的最大優勢。

我們致力於提供個性化、高效能的高階儀表儀器設計與定製服務,滿足設備實際的特定需求。

1.設備體型:

尺寸、形狀、大小,根據的需求進行調整,確保設備完美契合工作環境。

2.電子零件:

可以修改或更換電子零件,以滿足特定需求或技術規格。

3.修改設備功能:

根據應用場景,調整設備功能,使其更符合您的實際需求。

4.訊號處理:

進行訊號處理,包括放大、縮減、前置處理等,以確保您獲得高品質的數據。

5.維修和技術支援:

完善的維修服務和技術支援,讓己停產將面臨淘汰的設備能夠長時間穩定運行。

6.觸控畫面:

工控儀器檢測系統,設計使用者操控及管理者管理介面。

7.功能擴充、系統整合:

根據您的需求,功能擴充是從原有的儀器設備功能,到設備系統整合化與支援擴充多台設備,以提升設備間的整合性能。